Fire test facilities

We offer research and testing opportunities at our Werribee campus for applications in fire safety engineering.

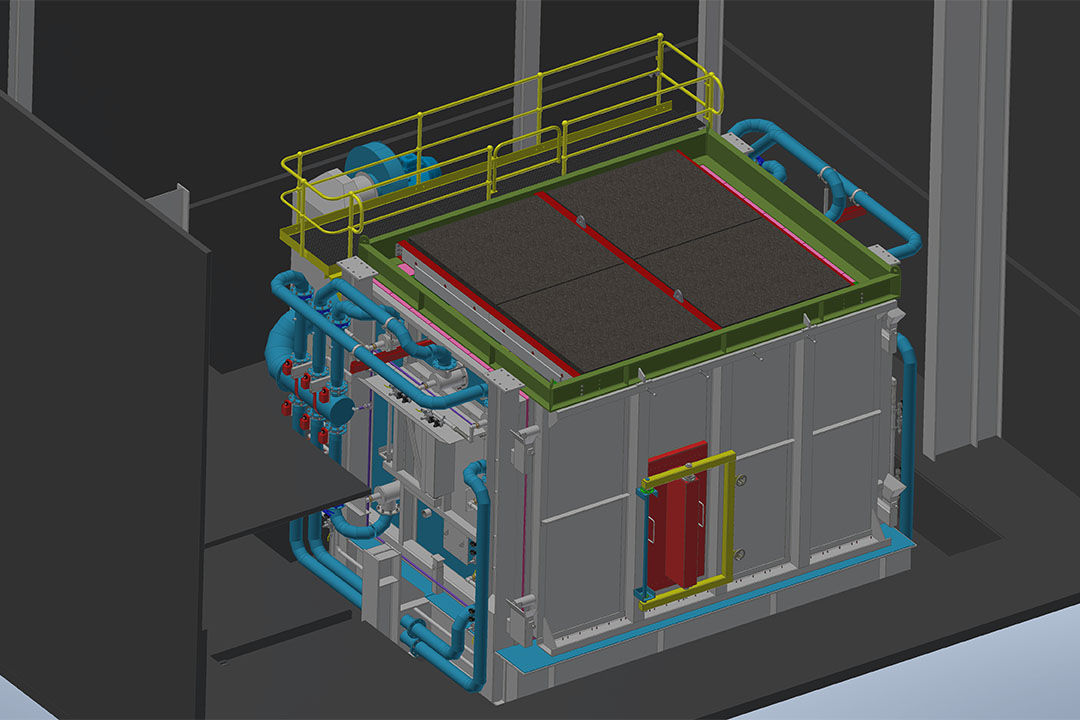

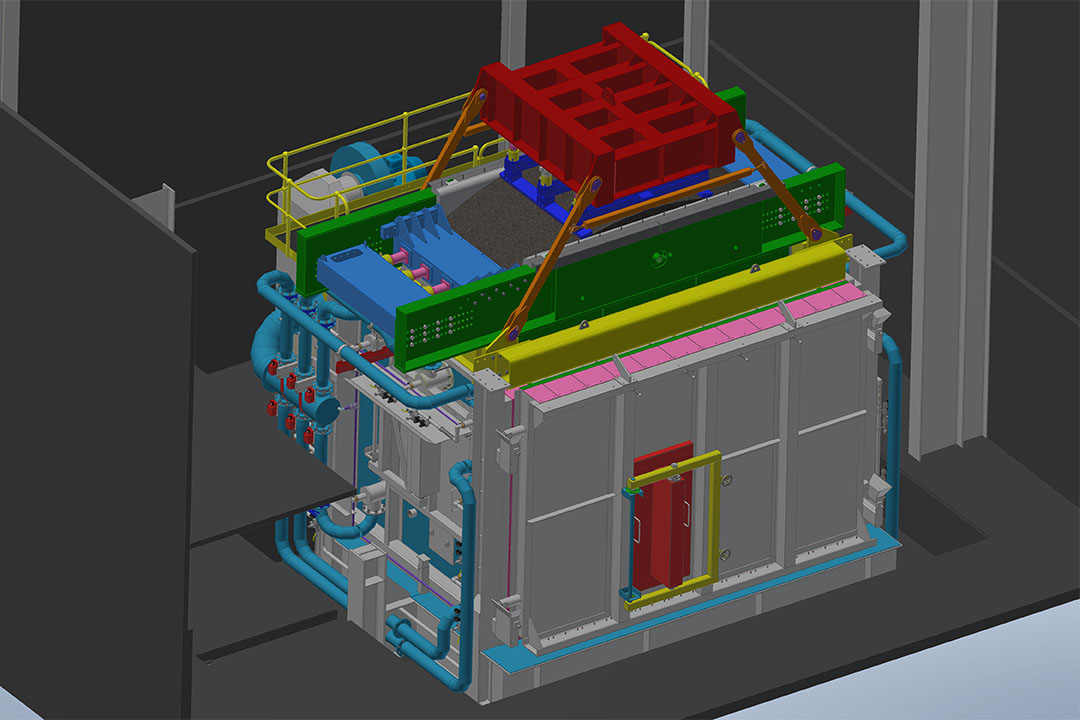

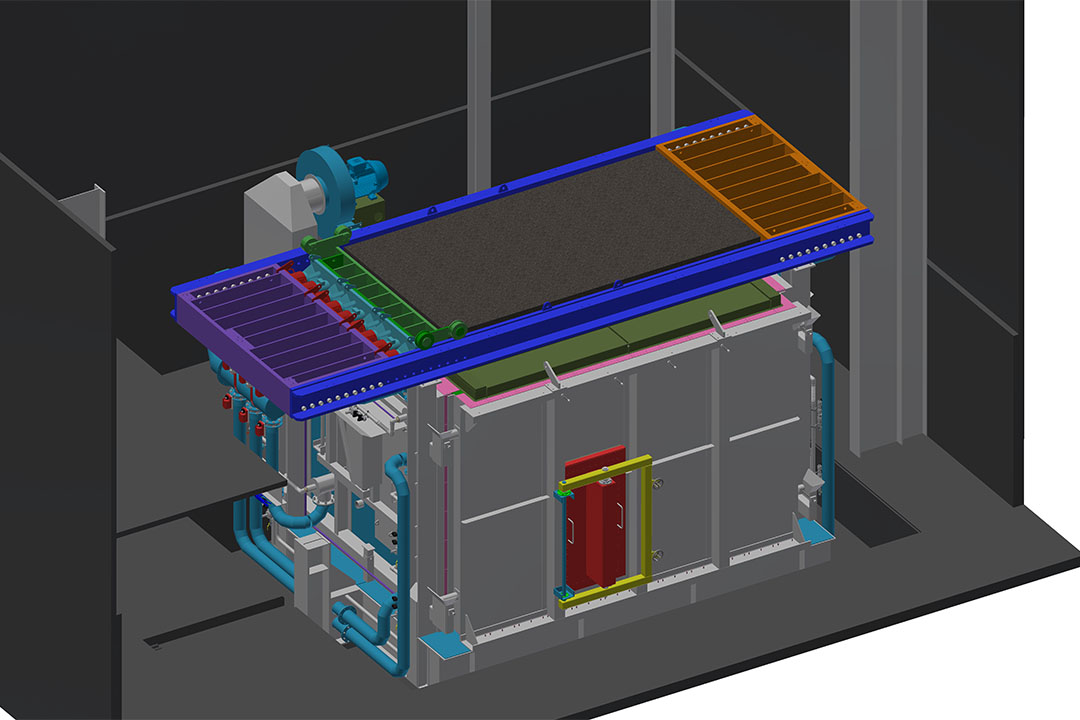

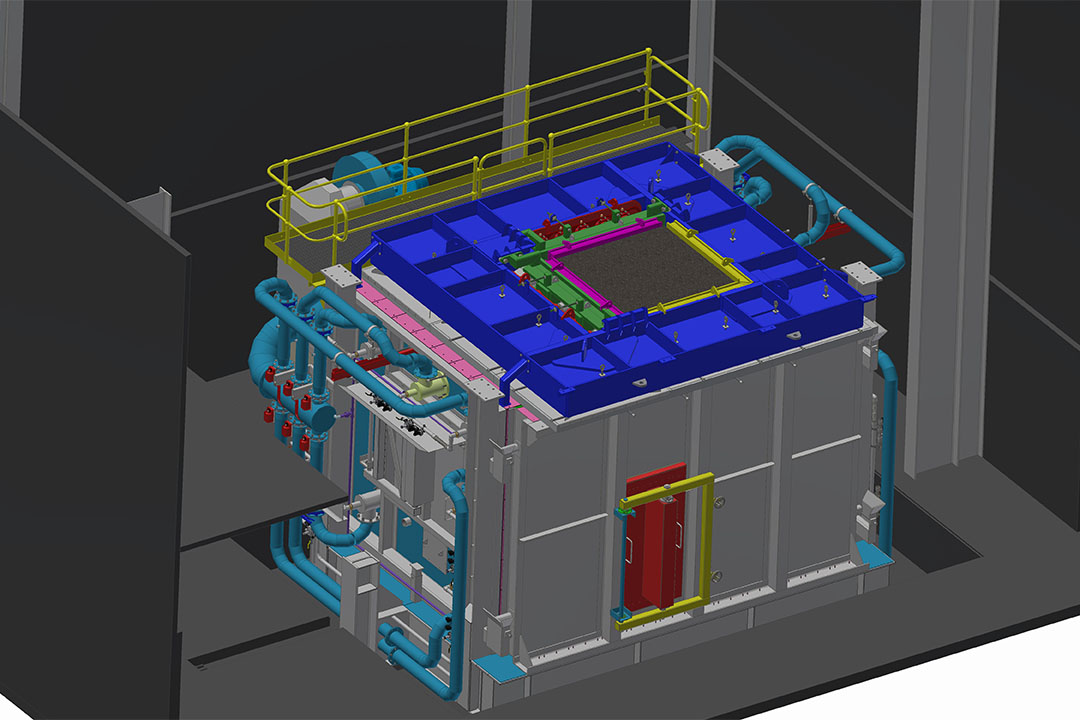

Fire test furnaces

We have installed a unique large scale structural fire test furnace capable of testing structures under combined structural and fire loading. The fire testing facility is located at Victoria University's Werribee Campus.

The furnace is designed to fire conditions, such as those found in European tunnel fire scenarios. Vertical loading in any configuration up to 250 Ton and horizontal loading of up to 100 Ton is possible.

The furnace is capable of providing fire resistance rating to AS 1530.4, BS 476 Parts 20–24, ISO 834, ISO 3008, ISO 3009 and ASTM E119. In addition, the furnace can test to 2008 -“Efectis-R0695 Fire testing procedure for concrete tunnel linings” and 2006 EFNARC – “Specification and Guidelines for Testing of Passive Fire Protection for Concrete Tunnels Linings”.

The furnace can test the following specimen configurations:

- Wall Specimens – 4550mm W x 3500mm H x 300mm D

- Floor Specimens – 4720mm L x 3745mm W x 300mm T

- Columns – 500mm W x 500mm D x 3000mm L

- Beams – 350mm W x 350mm D x 5000mm L

- Composite Panels – as specified

- T-beams – as specified

- Tunnel Elements – as specified.

The fire test furnace is capable of the following fire curves:

- RijksWaterStaat, NL (RWS)

- Modified HydroCarbon, FR (HCM)

- HydroCarbon Eurocode 1 (HC)

- RABT-ZTV (train) G

- RABT-ZTV (car), G

- ISO 834 Cellulosic Building.

Other equipment

Cone calorimeter

The cone calorimeter provides a method of testing the reaction of materials to heat exposure. In this test, small samples of materials (100 mm x 100 mm) are exposed to various levels of radiation.

The resulting products of combustion are drawn into a hood and analysed allowing various calculations, such as the mass loss and heat release rates, to be determined.

Due to the changes in building code and standards, we no longer provide the service to determine group number of a product.

3MW calorimeter & ISO room

The 3MW calorimeter is similar to the cone calorimeter but at a much larger scale.

It allows the burning characteristics (heat release rate versus time) to be established for a variety of items, such as furniture.

The characteristics burning these items directly under the hood or within an International Standards Organisation (ISO) room.

Measuring 3.6 m x 2.4 m x 2.4 m high, an ISO room is a standard for tests that allow the evaluation of lining materials giving a good indication of how they might behave in buildings.

Benchtop equipment

Equipment for toxicity analysis

- Fourier Transformation Infrared Spectrometry

- Gas Chromatography Mass Spectrometry

Equipment for thermal degradation

- Thermo-gravitimetric Analyser (TGA)

- Differential Scanning Calorimeter (DSC)

Equipment for thermo-physical parameter

Hot Disk Analyzer (HDA)